What is a CMMS? A Simple Guide for Facility & Maintenance Teams

Facility and maintenance teams work hard every day to keep buildings, equipment, and operations running smoothly. But as tasks grow and equipment becomes more advanced, using paper checklists or spreadsheets to manage maintenance no longer works well. That’s where a CMMS comes in.

If you’ve ever wondered what a CMMS is, what it does, or how it can help your team, this guide will give you the answers. We’ll also explain who uses it, why it’s better than old methods, and how to pick the right one for your facility. So, let’s get started.

What is a CMMS?

Are you wondering what CMMS means? CMMS stands for Computerized Maintenance Management System. It is a software tool that helps manage maintenance tasks, track assets, and keep everything organized. Instead of writing things down or keeping notes in Excel, a CMMS lets you store and manage all maintenance information in one place.

It works like a digital assistant for your maintenance team. It reminds you when work needs to be done, helps assign tasks, and keeps records of all your repairs and maintenance activities.

What Does a CMMS Do?

A CMMS does many things that make a maintenance team’s job easier. Some of the most important tasks it helps with include:

- Work Order Management: You can create work orders, assign them to team members, track their status, and mark them as complete.

- Asset Tracking: It keeps a record of all your equipment, including repair history, parts used, and maintenance schedules.

- Preventive Maintenance: You can set schedules for regular maintenance, so problems are fixed before they become bigger.

- Inventory Management: It helps you track tools and spare parts, so you don’t run out when you need something.

- Reports and Insights: You can see reports on how your team is performing, what tasks take the most time, and where you can improve.

- Mobile Access: Many CMMS tools work on phones or tablets, so your team can update tasks or check schedules on the go.

With these features, a CMMS makes it easier to stay on top of maintenance work and reduce unexpected issues.

Who Uses a CMMS?

A CMMS can be used by anyone responsible for maintaining physical assets or facilities. It’s not just for big companies. Even small teams benefit from having everything in one place.

Common users include:

- Facility Managers: Oversee buildings, utilities, and support systems.

- Maintenance Technicians: Perform repairs, inspections, and routine service.

- Operations Managers: Plan and improve workflows while avoiding disruptions.

- IT and Asset Teams: Track and manage technical equipment and infrastructure.

- Contractors and External Vendors: Access and complete assigned work securely.

Industries that rely on CMMS:

- Education: Schools and universities for building repairs, classroom equipment, and utilities.

- Healthcare: Hospitals and clinics where equipment uptime is critical.

- Hospitality: Hotels and resorts for guest room maintenance, elevators, HVAC, etc.

- Manufacturing: Factories that need constant equipment care to avoid downtime.

- Real Estate: Property managers overseeing multiple buildings and tenants.

- Retail: Stores and shopping centers for lighting, security, refrigeration, and more.

Even nonprofits and government departments use CMMS software to manage public buildings and community infrastructure.

Why Use a CMMS Instead of Spreadsheets or Paper?

Many facility teams start with simple tools like Excel or paper forms to manage tasks. While this might work at first, problems usually show up as the workload grows. Over time, it’s easy to lose track of what was done, who did it, and when it needs to be done again.

Spreadsheets don’t alert you when it’s time to replace a part or schedule the next inspection. Paper logs can’t tell you if a machine is breaking down more often than usual. These methods also rely heavily on manual updates, which can lead to missed tasks, outdated records, or even safety issues.

A CMMS, on the other hand, does the thinking for you. It stores all data in one place, updates records automatically, and gives reminders for upcoming work. You don’t have to guess when a task was last done or dig through files to prepare for an audit. It’s all ready with a few clicks.

Another big reason to switch is time. Facility managers often spend hours putting together reports for upper management or regulators. With a CMMS, those reports are created in seconds. This time saved can be used for planning improvements, managing vendors, or helping your team.

Also, if a key employee leaves or is unavailable, their knowledge doesn’t disappear with them. A CMMS keeps that information safe and accessible to the whole team. That kind of continuity is hard to achieve with spreadsheets or physical records.

Here’s a quick comparison:

Old Methods | CMMS Software |

Easy to lose or forget | Everything is saved in one place |

No automatic reminders | Sends alerts and updates automatically |

Hard to track asset history | Keeps full records for every asset |

Manual reporting | Creates reports with a few clicks |

Not mobile-friendly | Works on phones and tablets |

Using a CMMS means less time spent on paperwork and more time focusing on actual maintenance work. It also helps prevent mistakes and delays that often happen with manual tracking.

Key Benefits of a CMMS

- Minimizes Equipment Downtime A CMMS helps you stay ahead of problems by organizing preventive maintenance schedules. This reduces unexpected breakdowns and keeps machines running efficiently, which helps avoid disruptions in your daily operations.

- Streamlines Work Order Management You can quickly create, assign, and monitor work orders from one platform. This ensures nothing slips through the cracks, and team members always know what tasks are waiting for them, without relying on back-and-forth messages or sticky notes.

- Controls Maintenance Costs Regular checks reduce the chances of expensive emergency repairs. With a CMMS, you can also avoid overstocking parts or losing track of tools, helping you control both short-term expenses and long-term equipment investments.

- Increases Operational Visibility A CMMS gives you a real-time view of ongoing work, asset health, inventory levels, and team performance. This transparency helps you quickly identify delays or issues and act before they turn into major problems.

- Builds a Central Knowledge Base All asset manuals, service histories, checklists, and maintenance logs are stored in one digital hub. New or rotating staff can easily access this information to understand how to handle equipment without relying on senior technicians.

- Enhances Inventory Management You can monitor spare parts usage and set up alerts for low stock levels. This avoids last-minute runs for missing parts and ensures that your team always has what it needs to perform tasks on time.

- Supports Better Long-Term Planning Historical maintenance data helps you predict when assets may need repairs or replacement. This allows for smarter capital planning and reduces the chances of being caught off guard by costly equipment failures.

- Encourages Accountability When tasks are logged in a CMMS, it’s clear who is responsible for each job and when it was completed. This builds a sense of ownership and improves individual and team performance over time.

- Simplifies Reporting and Insights With built-in analytics and reporting tools, you can track KPIs like mean time to repair (MTTR), cost per work order, or asset downtime trends. These insights support data-driven decisions for maintenance improvements.

- Adapts to Any Facility Type Whether you’re managing a school, hospital, factory, hotel, or office building, a CMMS can be customized to fit your specific maintenance needs. You can scale up or down, adjust workflows, and create rules based on your team’s structure.

- Improves Internal Communication Since everyone works from the same platform, updates, comments, and progress tracking are shared in real time. This improves coordination between shifts and reduces the risk of miscommunication.

- Boosts User Satisfaction Faster response times, smoother repairs, and more reliable equipment directly impact the people who use your facility. Whether they’re employees, tenants, or visitors, they’ll notice the difference when maintenance runs smoothly.

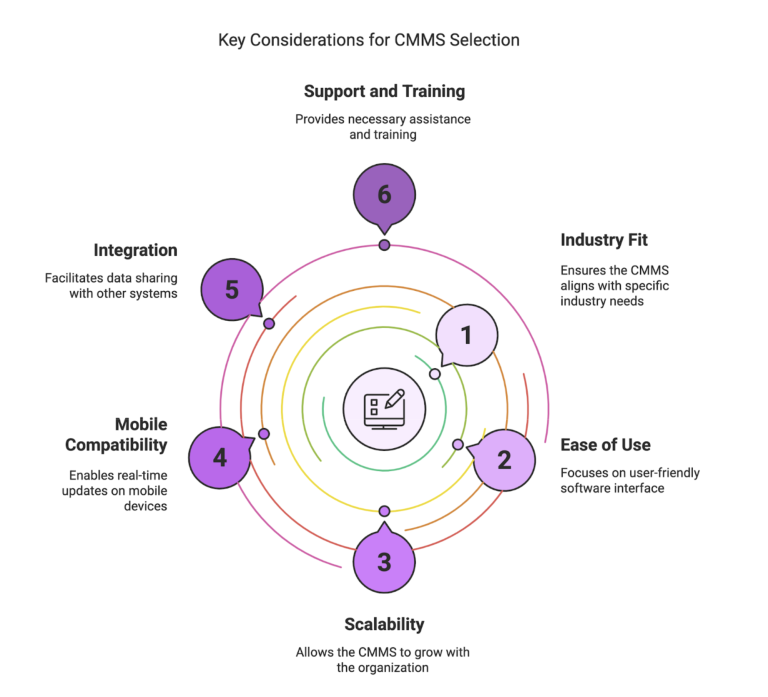

Choosing the Right CMMS in 2025

1. Fits Your Industry

Choose a CMMS that supports your type of facility, whether it’s a school, hospital, factory, or office. Some systems offer industry-specific features.2. Easy to Use

The software should be simple for your team to learn and use. A complicated system can cause delays and confusion.3. Grows with You

Look for a CMMS that can scale as your team or the number of locations grows. This way, you won’t need to switch systems later.4. Works on Mobile

Many technicians work in the field. Make sure your CMMS works well on phones and tablets, so updates can happen in real time.5. Connects with Other Tools

If you use other systems for inventory, finance, or HR, it helps if your CMMS can connect to them for better data sharing.6. Offers Support and Training

Make sure the company provides help when you need it. Good training and support can make a big difference, especially when getting started.

Bringing It All Together

A CMMS is more than just software, it’s a powerful tool that helps maintenance and facility teams work smarter. It replaces outdated systems like spreadsheets and paper checklists with one organized, easy-to-use platform.

By using a CMMS, your team can stay on top of tasks, reduce costs, keep assets in better shape, and improve overall performance. Whether you manage one building or many, a good CMMS gives you better control and visibility over your work.

Now that you know what a CMMS is, what it does, and why it matters, you can take the next step toward making maintenance more efficient and less stressful in 2025.

Why Choose Fixalert CMMS?

Fixalert is a modern, cloud-based CMMS designed to streamline maintenance operations across various industries. Its user-friendly interface and robust features make it an ideal choice for organizations aiming to enhance efficiency and reduce downtime.

If you’re looking for a modern, easy-to-use CMMS that checks all the boxes above, Fixalert is a smart choice.